The Importance of Simulation in the Plastics and Polymer Engineering Sector

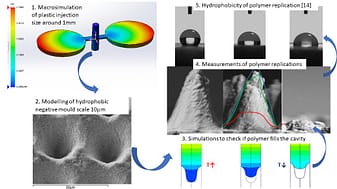

In the rapidly evolving field of plastics and polymer engineering, simulation technologies are revolutionizing product design, manufacturing processes, and material optimization. The ability to predict performance, enhance efficiency, and reduce costs has made simulation an indispensable tool in the industry.

Polymers 2021, 13(13), 2069; https://doi.org/10.3390/polym13132069

Why Simulation Matters

Simulation software enables engineers to model and analyse the behaviour of polymers under different conditions before physical prototypes are created. This reduces trial-and-error experiments, minimizes material wastage, and accelerates product development cycles. Some of the key benefits include:

• Optimized Product Design: Simulation allows engineers to predict how a plastic part will perform under mechanical, thermal, and chemical stresses, ensuring better durability and functionality.

• Process Efficiency: Advanced simulation tools can analyse injection molding, extrusion, and blow molding processes, helping manufacturers fine-tune parameters for improved yield and reduced defects.

• Material Innovation: By modeling the molecular structure and behaviour of polymers, researchers can develop new materials with enhanced properties, such as increased strength, flexibility, or thermal resistance.

Key Simulation Tools in the Industry

Several specialized software solutions are widely used in plastics and polymer engineering:

1. Moldflow (Autodesk) – A leading tool for simulating injection molding processes, helping identify potential defects like warpage, shrinkage, and air traps.

2. ANSYS Polyflow – Used for analysing polymer processing methods such as extrusion and thermoforming.

3. COMSOL Multiphysics – Enables engineers to study multi-physics interactions in polymer materials.

4. Digimat – A software suite that predicts the behaviour of composite and reinforced polymers.

Real-World Applications

Many industries leverage simulation to enhance their plastic product development and manufacturing processes:

• Automotive: Lightweight polymer components are simulated for impact resistance and structural integrity before being incorporated into vehicle designs.

• Medical Devices: Biocompatible polymers are modelled to ensure safety and performance in medical implants and devices.

• Packaging: Blow molding and thermoforming simulations help manufacturers optimize packaging designs for durability and sustainability.

• Aerospace: High-performance polymer composites are analyzed for heat resistance and mechanical strength in aerospace applications.

The Future of Simulation in Plastics Engineering

With advancements in artificial intelligence and machine learning, simulation software is becoming more predictive and autonomous. Digital twins—virtual replicas of physical products—are gaining traction, allowing real-time monitoring and optimization of plastic manufacturing processes.

As the industry moves towards sustainability, simulation is playing a crucial role in designing eco-friendly materials and optimizing recycling processes. Companies investing in simulation technologies today are positioning themselves for a more efficient, cost-effective, and innovative future in plastics and polymer engineering.

Simulation has transformed the way plastics and polymer engineering industries operate. By enabling precise modeling, reducing costs, and improving product quality, it has become an essential tool for engineers and manufacturers. As technology continues to evolve, simulation will remain at the forefront of innovation, helping industries meet growing demands with efficiency and sustainability.

This Blog by Dr. Kiran D. Patil, Dean School of Engineering and Provost-Incharge, PlastIndia International University.

Similar Posts:

BTech Lateral Entry Through LEET: Eligibility & Admission Process

Government Jobs After CIPET Diploma Courses

Why CIPET Courses Are in High Demand in the Plastics & Polymer Industry

What Is Lateral Entry Engineering after a Diploma? Complete Guide

Career Opportunities After CIPET Diploma Courses

Top Skills You’ll Gain in a Plastic Engineering Course

Benefits of Direct Second Year Engineering Admission for Diploma Holders

The Importance of Professional Communication and Soft Skills for Engineering Students

The Blending of Mathematics and Polymers in Shaping the Future of Plastics

Innovations and Developments in Plastics and Polymer Engineering – Shaping the Future

The Journey of Polly the Plastic Bead: A Tale of Plastic Engineering

PLASTICS: A MULTIDISCIPLINARY INDUSTRY

Plastics: Play a Crucial Role as Life Saving Material in Modern Healthcare, Food Packaging and Daily Life

Modern Plastics: Circular Economy and Sustainability

Plastic Eating Bacteria and Microbes: A Potential Solution Towards Environment Sustainability

Circular Economy in the Indian Plastics Industry: A Path Towards Sustainability

The Future of Plastics: The Integral Role of Computer Science Engineering

From Waste to Wealth: Innovations in Plastic Recycling

From Classroom to Industry: Exploring Careers in Plastics Engineering

Speciality Polymers in Industry: Transforming the Future

The role of Plastic and Polymer Graduates in the Plastic molding industry

PIU and the Future of Plastics: A UMass Lowell Legacy of Innovation

Plastics: Pioneering Invention to Sustainable Innovations

An Engineer’s perspective on Plastics: Beyond Buckets and Mugs

Sustainable Edge of Plastics in Modern Life