The role of Plastic and Polymer Graduates in the Plastic molding industry

These processes are vital in manufacturing countless products across various sectors, including automotive, packaging, medical devices, and consumer goods. The molding industry is the backbone of countless manufacturing processes. Its where raw polymer materials are transformed into the everyday products we rely on. At its core, molding is about shaping plastic into precise forms, whether it’s a simple container or a complex automotive component. To truly understand the potential careers in this field, we must first appreciate the intricacies of the processes involved.

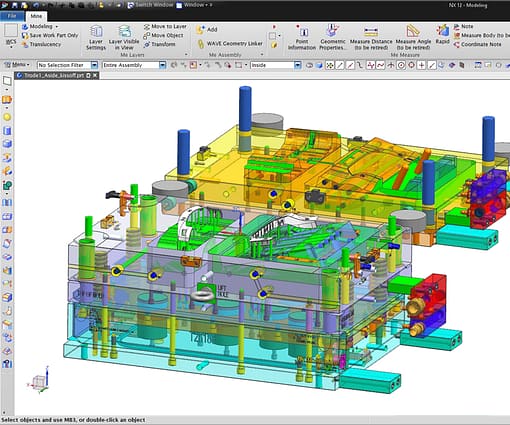

Imagine the journey of a product from concept to reality. It often begins with the design of a mold, a critical step that requires a deep understanding of material properties and manufacturing constraints. Mold design engineers play a pivotal role here, using sophisticated CAD/CAM software to create virtual models that are both functional and manufacturable. They must consider factors like shrinkage, cooling rates, and ejection mechanisms to ensure the final product meets stringent quality standards. This process is not just technical; it’s an art, requiring creativity and problem-solving skills to overcome design challenges.

CAD/CAM Software Brings Process Automation for Mold Design, Machining (https://www.mmsonline.com/articles/cadcam-software-brings-process-automation-for-mold-design-machining)

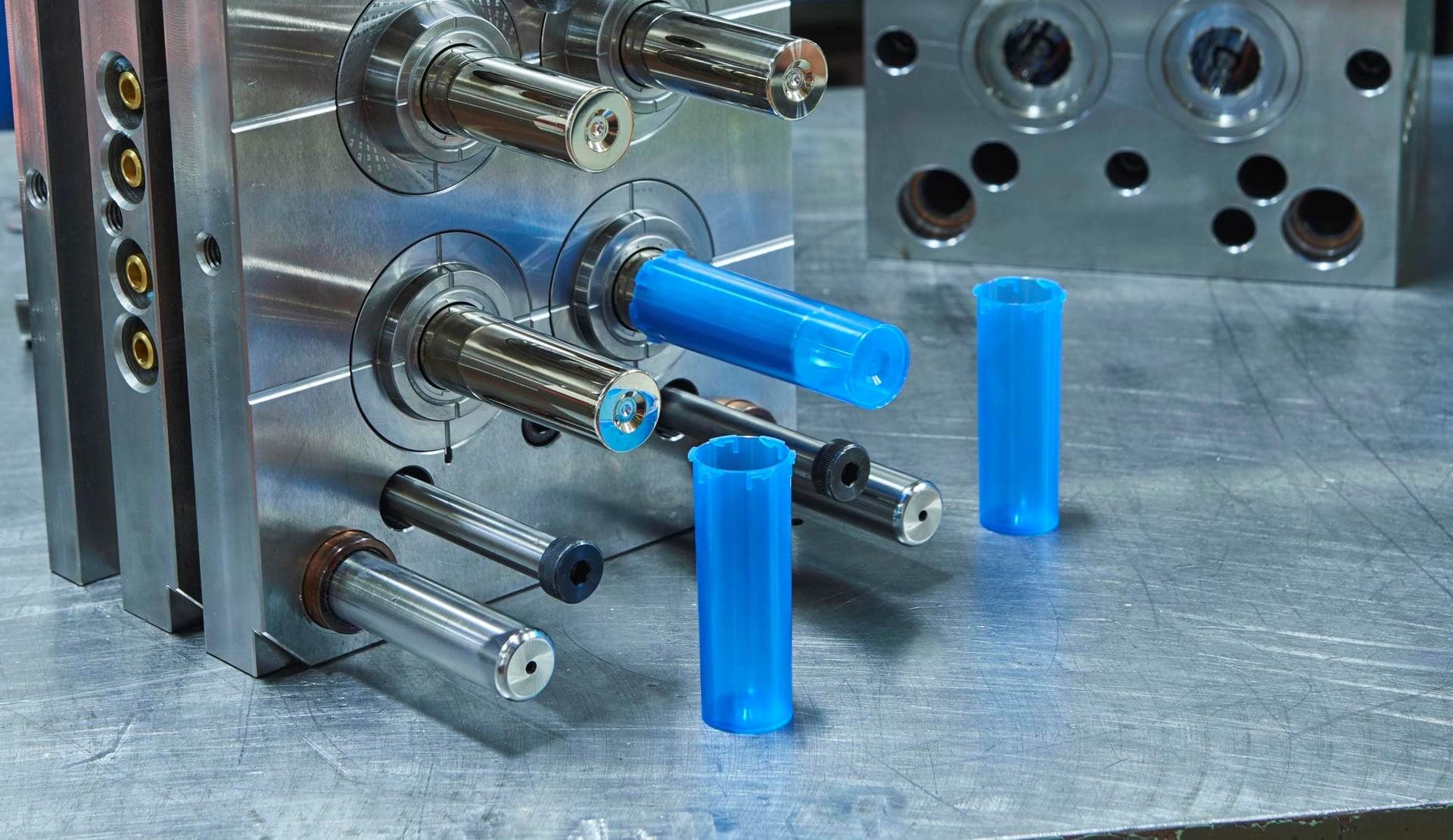

Once the mold design is finalized, the focus shifts to manufacturing. This is where process engineers’ step in, optimizing the molding process for efficiency and quality. They work with various molding techniques, such as injection molding, blow molding, and thermoforming, each with its unique set of parameters. For instance, in injection molding, they control variables like melt temperature, injection pressure, and cooling time to achieve the desired part characteristics. Their work ensures that every product is produced consistently and meets the required specifications.

Injection mold with product (https://commons.wikimedia.org/wiki/File:Injection_Moulding.jpg)

With a B. Tech. in Polymer Engineering, you are well-equipped to pursue diverse and rewarding careers in the molding industry. Here are some key roles:

- Manufacturing engineers play a crucial role in overseeing the production of molds and plastic parts. They ensure that production lines run smoothly, troubleshoot any issues that arise, and implement continuous improvement initiatives. Their expertise in manufacturing processes and equipment is essential for maintaining productivity and minimizing downtime. This role demands a blend of technical knowledge and leadership skills, as they often manage teams of technicians and operators.

- Quality control engineers are the guardians of product quality in the molding industry. They implement rigorous testing procedures to ensure that every part meets the required standards. This involves using advanced measurement tools and techniques to verify dimensions, surface finish, and mechanical properties. Their attention to detail and commitment to quality are vital for maintaining customer satisfaction and preventing costly defects.

- Materials engineers are another essential part of the molding industry. They select and test polymer materials for specific applications, considering factors like strength, durability, and chemical resistance. Their expertise ensures that the right material is used for each product, optimizing performance and longevity. They also stay abreast of the latest advancements in polymer technology, exploring new materials and additives that can enhance product properties.

- Research and development engineers are the innovators of the molding industry. They develop new molding techniques, explore alternative materials, and improve existing processes. Their work drives the industry forward, leading to more efficient and sustainable manufacturing practices. They are constantly pushing the boundaries of what’s possible, creating new solutions to meet the evolving needs of the market.

- In addition to these technical roles, there are also management positions that offer exciting career paths. Production managers, for example, oversee the day-to-day operations of molding facilities. They manage production schedules, allocate resources, and ensure that production targets are met. Their leadership skills and ability to motivate teams are essential for success in this role. The Technical Sales Engineers bridge the gap between technology and business. They provide technical expertise to clients, helping them select the right molding solutions for their needs. Their ability to communicate complex technical concepts in a clear and concise manner is crucial for building strong client relationships and driving sales.

At Plastindia International University, we understand the importance of preparing our students for these diverse and rewarding careers. Our comprehensive B. Tech Polymer Engineering program provides a strong foundation in polymer science and engineering, combined with hands-on experience in our state-of-the-art laboratories. We are committed to fostering an environment of innovation and collaboration, empowering our students to become leaders in the molding industry.

The molding industry is constantly evolving, driven by advancements in materials, technologies, and sustainability. As a polymer engineer, you will play a crucial role in shaping the future of this dynamic sector. We invite you to explore our B. Tech in Plastics and Polymer Engineering program and embark on a fulfilling career in the molding industry.

Join us at Plastindia International University, where innovation meets opportunity.

Dr. Prashant Gupta, Sr. Asst. Professor, School of Engineering, Plastindia International University.

Similar Posts:

Why CIPET Courses Are in High Demand in the Plastics & Polymer Industry

What Is Lateral Entry Engineering after a Diploma? Complete Guide

Career Opportunities After CIPET Diploma Courses

Top Skills You’ll Gain in a Plastic Engineering Course

Benefits of Direct Second Year Engineering Admission for Diploma Holders

The Importance of Professional Communication and Soft Skills for Engineering Students

The Blending of Mathematics and Polymers in Shaping the Future of Plastics

Innovations and Developments in Plastics and Polymer Engineering – Shaping the Future

The Importance of Simulation in the Plastics and Polymer Engineering Sector

The Journey of Polly the Plastic Bead: A Tale of Plastic Engineering

PLASTICS: A MULTIDISCIPLINARY INDUSTRY

Plastics: Play a Crucial Role as Life Saving Material in Modern Healthcare, Food Packaging and Daily Life

Modern Plastics: Circular Economy and Sustainability

Plastic Eating Bacteria and Microbes: A Potential Solution Towards Environment Sustainability

Circular Economy in the Indian Plastics Industry: A Path Towards Sustainability

The Future of Plastics: The Integral Role of Computer Science Engineering

From Waste to Wealth: Innovations in Plastic Recycling

From Classroom to Industry: Exploring Careers in Plastics Engineering

Speciality Polymers in Industry: Transforming the Future

PIU and the Future of Plastics: A UMass Lowell Legacy of Innovation

Plastics: Pioneering Invention to Sustainable Innovations

An Engineer’s perspective on Plastics: Beyond Buckets and Mugs

Sustainable Edge of Plastics in Modern Life